Description

Standard: BS 1377-4, 1924-2, EN 13286-2, EN 13286-47

Proctor CBR Soil Compactor, Automatic, Eco Smartz (ASTM/AASHTO) NL 5025 X / 005A

Proctor CBR Soil Compactors, Automatic

Proctor CBR (California Bearing Ratio) Soil Compactor is used for proctor compaction tests on soil samples, allowing for determining maximum dry density and optimum moisture content in geotechnical engineering according to standardized procedures. This process involves compacting soil samples in a standard mold under controlled conditions. This helps evaluate the mechanical strength of natural ground, subgrades, and base courses for pavement design, measuring the load-bearing capacity of soil when compacted to specific density and moisture content.

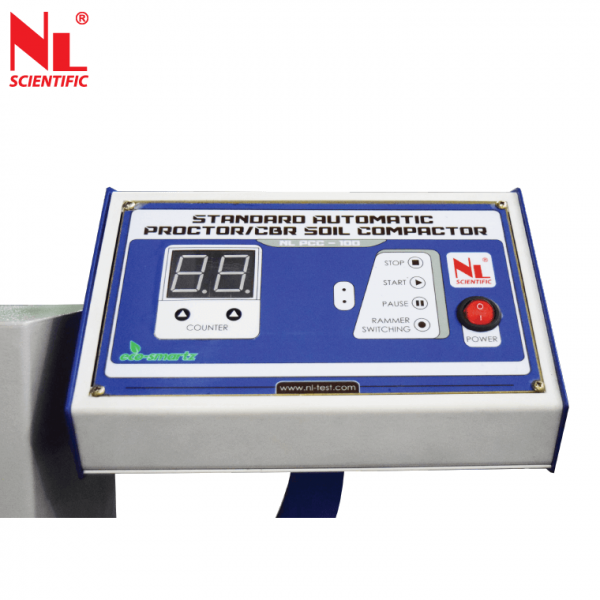

Newly upgraded model by using ECO-SMARTZ system for energy saving and consistency operation. Solid and compact design allows uniform and correct compaction of Proctor and CBR samples.

Proctor CBR Soil Compactor, Automatic, Eco Smartz (BS/EN) NL 5025 X / 005B

Proctor CBR Soil Compactor, Automatic, Eco Smartz (BS/EN)

Proctor CBR Soil Compactor, Automatic (BS/EN) is used to test soil properties in construction and geotechnical engineering. This compact unit is capable of automatically performing two key sets: the Proctor test and the California Bearing Ratio (CBR) test. The Proctor test helps determine soil compaction characteristics by assessing maximum density and optimal moisture content, while the CBR test evaluates soil strength for road construction. Automation streamlines the testing process, enhancing efficiency, accuracy, and productivity. By automating these tests, the compactor ensures consistency and reliable results, making it an invaluable tool for soil analysis in construction projects.