Description

Standard: EN 196-1, ASTM C 305, AASHTO T 162, ISO 679

Compression & Flexural

Digimatic Compression Machine 2000kN NL 4000 X / 032G

Digimatic Compression Machine 2000kN

The Digimatic Compression Machine 2000kN is designed for meticulous evaluation of material properties through compression testing. Its digital interface, comprising displays, controls, and data logging features, ensures enhanced accuracy and ease of operation compared to traditional analog machines. Specializing in compression testing, it subjects materials to compressive forces until deformation or failure, providing insights into crucial mechanical properties such as strength and elasticity. With a formidable maximum force capacity of 2000 kilonewtons (kN), this machine accommodates a wide range of materials, from metals to concrete and composites, making it an indispensable tool for quality assessment, research, and development endeavors across various industries. NL Digimatic Compression Machine are special designed extremely strong and oversized to grant high rigidity and stability during testing. With a fixed upper head carring a ball-seated platen and base platen with 150 mm cube centering guide pin. Equipped with analogue loading speed indication knob.

Digimatic Compression Machine 2000kN (E-Version) NL 4000 X / 021

Digital Display Compression Testing Machine 2000kN

Compression Testing Machine is used to determine the compressive strength of concrete by gradually and uniformly applying compressive force to a concrete sample until it fails, crushing, or cracking. Maximum force applied before failure occurs is recorded and compressive strength of concrete is measured.

Digital Display Compression Machine 2000kN

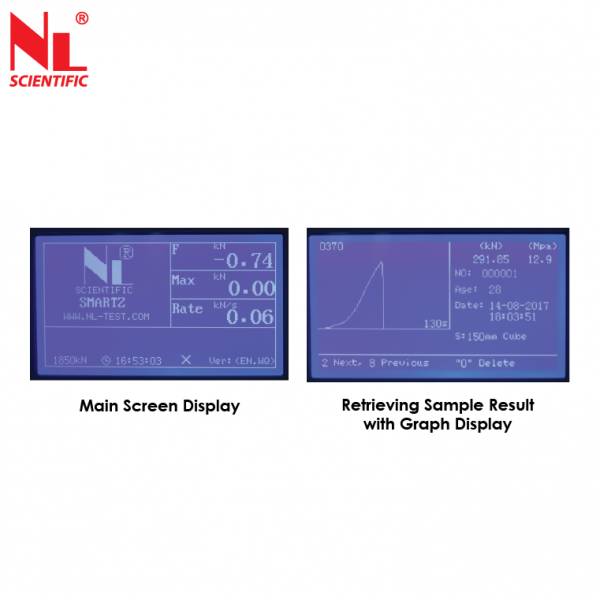

Digital Compression Machine is used to determine the compressive strength of concrete by gradually and uniformly applying specific compressive loads through a digital display. The compressive strength results will display on Graph Display Screen when failure, crushing, or cracking occurs.

The Digital Compression Testing Machine provides high precision in compressive strength testing and automatically records results, is capable of storing up to 500 specimen data sets, and comes with instant result printing compared to the Analogue Series which requires performing compressive strength tests and recording of results manually.

NL Digimatic Compression Machines are specially designed extremely strong and oversized to grant high rigidity and stability during testing. With a fixed upper head carrying a ball-seated platen and base platen with a 150 mm cube centering guide pin. Equipped with analog loading speed indication knob.